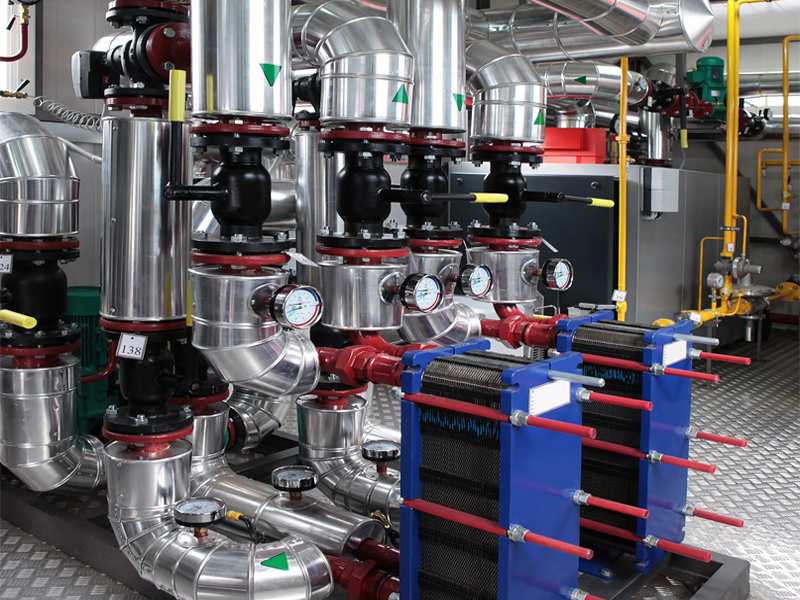

Insulated Heat Exchanger Box

Heat exchangers are devices designed to transfer heat through fluids. In an exchanger, there are two fluids, either in gas or liquid form, and heat transfer occurs between these substances without mixing. Plates are present in the exchangers, which prevent the fluids from mixing and facilitate heat transfer. They are used in various fields where there is a need for heating or cooling. Insulated heat exchanger boxes are made with a system that prevents heat loss.

Areas of Application for Insulated Heat Exchanger Boxes

These devices, produced for heat transfer, are used in air conditioners, boilers, central heating boilers, radiators used in cars, refrigerators, and other industrial and industrial-related areas. Insulated heat exchanger boxes can be used in many different areas, such as valve jackets, conveniently.

Types of Heat Exchanger Boxes

There are dismantlable plate heat exchangers, welded plate heat exchangers, semi-welded plate heat exchangers, and brazed plate heat exchangers. There are also tube-type heat exchangers. In addition to these, there are heat exchangers for special applications. Among the insulated heat exchanger boxes, we can mention three types of special application exchangers: platecoil, econocoil, and spiral.

Tubular Heat Exchangers

Tubular heat exchangers are devices that exchange heat through tubes. They are frequently used types of exchangers in large-scale chemical industry areas. They are also widely used in petroleum refineries. They have a design consisting of small tubes within a large tube. One of the two fluids, cold and hot, flows through the inner and outer tubes, respectively. In this way, heat is exchanged between the fluids. Energy is recovered and reused. Heat transfer also occurs along the tube surfaces.

Plate Heat Exchangers

In addition to tube heat exchangers, there are also various types of plate heat exchangers. Heat exchange occurs through the plates called PIDs. These plates have channels. There are both movable and stationary bodies. The plates are mounted here, carried by the bottom and top bars. The fluids are fed through pressure plates. The plate guide consists of two channels. Through these channels, the fluids flow through the gaps between the plates as they go to the heat exchanger. They do not mix with each other during this process. The working system of plate heat exchangers is as described for insulated heat exchanger boxes.

Heat exchangers are important devices in terms of their areas of use. Heat regenerators are used to store products for long periods without spoiling. When the products are sterilized, they can remain intact within the ambient temperature. Companies operating in the food industry benefit from these exchangers. This enables the transportation of products to distant places without spoilage. These exchangers offer many advantages for companies and customers in the food sector. The use of heat exchangers is widespread. They are cost-effective devices and highly functional in terms of heating and cooling. They provide a hygienic environment for liquid foods and protect them from potential damages. Milk is heated and cooled through a process called pasteurization to be ready for distribution. Heat exchangers have many applications in such areas.